Description

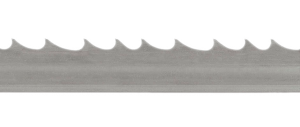

Exceptionally solid construction of the saw band arm and the massive dual-column arm support moving on linear lines ensure excellent stiffness of the whole system and accurate cut during industrial cutting of full materials. Robust industrial saw blade 67 x 1.6 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel. For easier feed of heavy materials, the loading area is equipped with a pass-through roller track with a load-carrying capacity of 10 t/m. Full uplift vice ensures a quick and reliable workpiece clamping during cutting. The vice jaw together with the movable guide head of the saw blade are automatically adjusted on the linear guiding. Thus, it is located as close to the cut as possible, which contributes to the accuracy and speed of the cut and to the service life of the saw blade. Both guide heads of the saw blade are equipped with automatic control of the feed to the cut. The system monitors the current load on the saw blade and provides automatic coordination of an ideal cutting pressure and feed, considering the current profile of the material. This significantly speeds up as well as gives precision to the cut and increases the service life of the saw blade. Hydraulic saw blade tensioning controlled from the central panel ensures optimum tension and control of it during the operation of the machine. Optimum tensioning of the saw blade is essential for the service life of the saw blade and for the cutting accuracy. Accurate guidance of the saw blade on the guide heads is ensured by hydraulically clamped solid carbide guiding plates. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw blade speed by a frequency converter in the range from 10 to 115 m/min, which significantly contributes to cutting accuracy and service life of the saw blades.

Ergonomic central control panel ensures easy control of the machine.

After material clamping and pressing of a single switch, the machine will execute complete cutting cycle – workpiece clamping, saw blade and cooling system start, cutting, saw blade and cooling stop, arm uplift to the original adjustable position above the material. When you switch to the manual mode, you can control all functions separately. Large robust base and overall massive framework guarantee exceptional stability of the machine even when cutting heavy workpieces. For a comfortable chip removal, the machine can be equipped with a rake chip conveyor. The machine is equipped with a high-performance industrial hydraulic unit. Hydraulic unit allows you to set the required pressure of the vice. Hydraulic blade tensioning guarantees perfect tensioning of the saw blade..

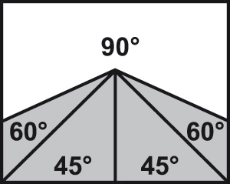

- In order to achieve maximum accuracy and productivity, the machine is designed only for upright cutting.

- Very robust machine construction composes of massive castings and ensures safe vibration absorption.

- Large diameter blade wheels and precise three-side solid carbide blade guides ensure long service life of the blade and cutting accuracy.

- Overdesign of blade wheel bearings, tensioning wheel system and all rotary parts ensure long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with bevel-spur gearbox.

- A circular steel brush powered by an industrial motor with a bevel-spur gearbox ensures removal of chips from the saw blade behind the cut.

- The machine is connected to a complete cooling system with a high-performance pump and possibility of regulating the flow on both guiding heads independently and on two additional adjustable outlets. Rinsing pistol is used for easy cleaning of the machine. Coolant tank of approx. 100 l with a high-performance pump are placed in the base of the machine.

- High-quality lighting of the work area by a line of powerful LEDs with a cover.

- The machine checks correct tension or breakage of the saw blade. If the saw blade breaks, the machine automatically switches off.