Description

The most up to date concept of the cast iron arm creates a closed section that is hollow along its full length at all load-carrying points. This guarantees outstanding stiffness of the entire system, maximum accuracy during cutting and a long service life of the saw blade. All of electrical wiring and coolant distribution are concealed in hollow parts of the arm, which means they are protected from damage. The new concept of the arm also brings a great simplification when changing the saw band or when cleaning the inside of the arm. You just need to open the hinged back cover of the arm and it will stay locked in the upper position. Apart from the new saw arm design, there are many technological adjustments that improve user comfort as well as the quality and durability of the machine.

Universal robust band saw is appraised for general use in continuous uninterrupted production plants and in work-shops (work on locks, maintenance) as well. Industrial band 27 x 0.9 mm is manufactured in many versions and allows for cutting of wide range of materials, including stainless steel or tool steel. The machine is equipped with high-performance industrial hydraulic unit. Pressing a single switch will execute complete cutting cycle – material clamping, band and cooling system start, cutting, band and cooling stop, arm uplift to the original adjustable position and vice unclamping. All of this in connection with hydraulics-controlled saw band feed into cut significantly increases cutting efficiency, especially in larger series and cutting of full and high-quality materials. When you switch to the manual mode you can control all functions separately. Hydraulic unit allows you to set the required pressure of the vice. Maximum cutting efficiency is maintained also thanks to the possibility of setting optimum saw band rate by a frequency converter in the range between 15 and 90 m/min., which significantly contributes to cutting accuracy and service life of saw bands. Large base and massive arm turning system with large loading surfaces ensure exceptional stability of the machine even when cutting heavy workpieces.

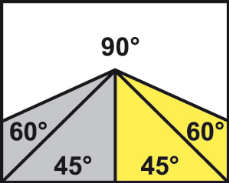

- Continuous adjustment of the cutting angle within the range 90°–60° when the workpiece is clamped tight.

- Very robust machine framework composes of castings from grey cast iron and ensures vibration absorption.

- Modern concept of the band saw arm allows for large cutting ranges in upright and angular cuts.

- Simple locking and adjusting of the desired cutting angle on the angle scale.

- Massive quick-clamping vice ensures easy and reliable material clamping.

- Large diameter running wheels and precise three-side hardmetal guiding ensure long service life of the band and cutting accuracy.

- Overdesign of running wheel bearings, tensioning wheel system and all rotary parts ensures long service life of the machine.

- Noiseless and maintenance-free band drive is provided by an industrial electric motor with worm gearbox.

- The machine is connected to a complete cooling system with a professional high-performance pump and possibility of regulating the flow on both guiding heads. Coolant tank with a The machine checks correct tension or break of the saw band. If the saw band breaks the machine automatically switches off.

- Easy control by ergonomically placed controls (electrical and hydraulics) on the base of the machine.

- The machine is equipped with a hinged stop with a 500mm scale. Hinged system prevents the workpiece from jamming during cutting.